Shop by Category

- Accessories

- Aspirator

- Cosmetics

- Digital Photography Systems

- Eyewear

- Footswitch/Foot Pedal

- Handpieces

- Infiltration Pump

- Laser Eyewear

- Microdermabrasion Devices

- Miscellaneous

- Portable Devices

- Skin Care Products and Make Up

- Skin Chillers

- Skin Sales Tools

- Smoke Evacuator

- Tips & Consumables

- Training & Business Tools

- User Manual/Operators Manual

- Les Encres

- Manufacturer

- Active Optical Systems

- Advalight

- Aerolase

- Aesthera

- Aesthetic Management Partners (AMP)

- Aesthetics Biomedical

- Aesthetika Lasers

- Alma Lasers

- Artas

- Asclepion

- Bella Products Inc.

- BTL Aesthetics

- Buffalo Filter

- Candela

- Canfield

- Cartessa

- Cellsound Aesthetics

- Cenmade

- Cervello

- Chromogenex

- CoolTouch

- Cutera, Inc.

- Cynosure, Inc.

- Deka

- Dermasweep

- DiamondTome

- Dornier

- Dusa

- Eclipse Aesthetics

- Edge Systems

- Eleme

- Ellman

- Emage Medical

- Emvera

- EndyMed

- Energist

- Equipmed

- Erchonia

- Fisioline

- Focus Medical

- Formatk

- Fotona

- Fraxel

- HK Surgical

- HOYA ConBio

- Human Med

- Hydrafacial

- Ilooda

- Inmode Aesthetic

- Iridex

- Jeisys

- Lasering

- LaserOptek

- Laserscope / Iridex

- Lazerlenz

- Light Bioscience

- Lipo Ltd

- Lumenis

- Lutronic, Inc.

- Mattioli

- Medical Laser Technolgies

- Medicamat

- MeDioStar NEXT

- Merz

- Miramar Labs

- NeoGraft

- Noir

- Noir Laser Eyewear

- Novoxel

- Nuvolase

- Nylo Aesthetics

- Obagi Medical

- Omnilux

- Other

- Palomar Medical

- Parisian Peel

- Photo Therapeutics

- Profect Medical Technologies

- Quanta Systems

- Quantel

- RA Medical

- Radiancy

- Reveal

- RevecoMed

- Rohrer Aesthetics

- Sandstone

- Sano Laser

- Sciton, Inc.

- Sharplight

- Sincoheren

- Solta Medical

- Storz Medical

- SupraMedical

- Sybaritic, Inc

- Syneron, Inc.

- Syntech Laser

- Thermage, Inc.

- Thermi Aesthetics

- Ulthera, Inc

- Ultra Aesthetica

- Venus Concepts

- Vibraderm

- Viora

- Vivace

- Viveve

- Wontech

- Zeltiq

- Zimmer

- Procedure

- Acne Scars

- Acne Treatment

- Acoustic Radial Shockwaves

- Actinic Keratosis

- Age Spots

- Body Contouring

- Body Contouring – Diode

- Body Contouring – Hands Free

- Body Contouring – Radio Frequency

- Body Contouring – Ultrasound & Radio Frequency Combined

- Cavitation

- Cellulite Smoothing

- Cherry Angiomas

- Collagen Regeneration

- Complexion Analysis

- Dental

- Dry Eye

- Dynamic Muscle Stimulation

- Epidermal Renewal

- Erectile Dysfunction

- Face Contouring

- Face Oil Reduction

- Facial

- Facial Muscle Stimulation Treatment

- Facial Redness

- Fat & Cellulite Reduction

- Fat Grafting

- Fractional Skin Resurfacing

- Freckles

- Hair Restoration

- Hyperhidrosis

- Hyperpigmentation

- Incontinence

- Keloid Scar Treatment

- Laser Hair Removal

- Laser Hair Removal – Diode

- Laser Lipolysis

- Liposuction

- Lymphatic Massage/Drainage

- Melanin Reduction

- Melasma Removal

- Microdermabrasion

- Microneedling

- Muscle Sculpting

- Non-Invasive Hair Growth Treatment

- Non-Surgical

- Oxygen Skin Therapy

- Pain Relief

- Photodynamic Therapy

- Photofacial Rejuvenation

- Pigment Reduction

- Pigmented Lesion

- Podiatry

- Pore Minimizer – Minimize Enlarged Pores

- Port Wine Stains

- Psoriasis

- Reverse Photo-aging Damage

- RF Microneedling

- Rosacea Treatment

- Scalp Health

- Scar Correction

- Seborrheic Keratosis

- Skin Analysis

- Skin Chilling

- Skin Rejuvenation – Ablative

- Skin Rejuvenation – Non-Ablative

- Skin Rejuvenation – Sublative

- Skin Resurfacing

- Skin Tags

- Skin Tightening

- Skin Tightening – Eye Area

- Spider Veins

- Sterilize

- Stretch Marks Removal

- Sun Spots

- Surgical

- Sweat Reducer

- Tattoo Removal

- Toenail Fungus

- Transepidermal Delivery

- Ulcer/Wound Healing

- Vaginal Rejuvenation

- Vascular Lesions

- Vascular Structure

- Vein Removal

- Warts

- Wrinkle Reduction

- User Manuals

- Wavelength

- 10,600 nm (CO2)

- 1060 nm (Diode)

- 1064 nm (Diode)

- 1064 nm (Nd Yag Long Pulse)

- 1064 nm & 755 nm

- 1064 nm, 755 nm & IPL

- 1100 – 1800 nm (Infrared)

- 1319 nm (Infrared Nd Yag)

- 1320 nm (Infrared Nd Yag)

- 1400 nm (Erbium Glass)

- 1440 nm Nd Yag

- 1450 nm (Diode)

- 1470 nm

- 1500 nm (Erbium Glass)

- 1540 nm Erbium Glass

- 1550 nm Erbium Glass

- 1565nm

- 1750nm (Infrared)

- 1927 nm (Thulium)

- 2790 nm (Erbium YSGG)

- 2940 nm (Erbium Yag)

- 308 nm (Xenon Chloride)

- 532 nm (KTP)

- 532 nm / 1064 nm (KTP / Nd Yag – Q-Switched)

- 585 nm (Pulsed Dye)

- 595 nm (Pulsed Dye)

- 635 nm (Diode)

- 650-660 nm (Diode)

- 670 nm

- 680 nm (Red Diode)

- 694 nm (Ruby)

- 700 nm

- 755 nm (Alexandrite)

- 800 nm (Diode)

- 805 nm (Diode)

- 808 nm

- 810 nm (Diode)

- 850nm (Infrared)

- 900 nm (Diode)

- 980nm (Infrared Diode)

- Acoustic Wave Therapy AWT

- AFT (Advanced Fluorescence Technology)

- AMP – Active Magnetic Pulse

- CO2

- Direct Bio-Electrical Muscle Stimulation

- ElectoFusion

- EMS (Electrical Muscle Stimulation)

- HIFEM (High Intensity Focused

- IPL (Broad Spectrum)

- LED (Light Emitted Diodes)

- LIESWT – Low- Intensity Extracorporeal Shock Wave Therapy

- Multi-Wavelength

- Nitrogen Plasma

- Radio Frequency

- Radio Frequency – Bipolar

- Radio Frequency – Monopolar

- Radio Frequency – Unipolar

- Shock Wave Therapy

- TMA – Thermo-Mechanical Action

- Tripollar RF

- Ultrasound

- Ultrasound & Radio Frequency

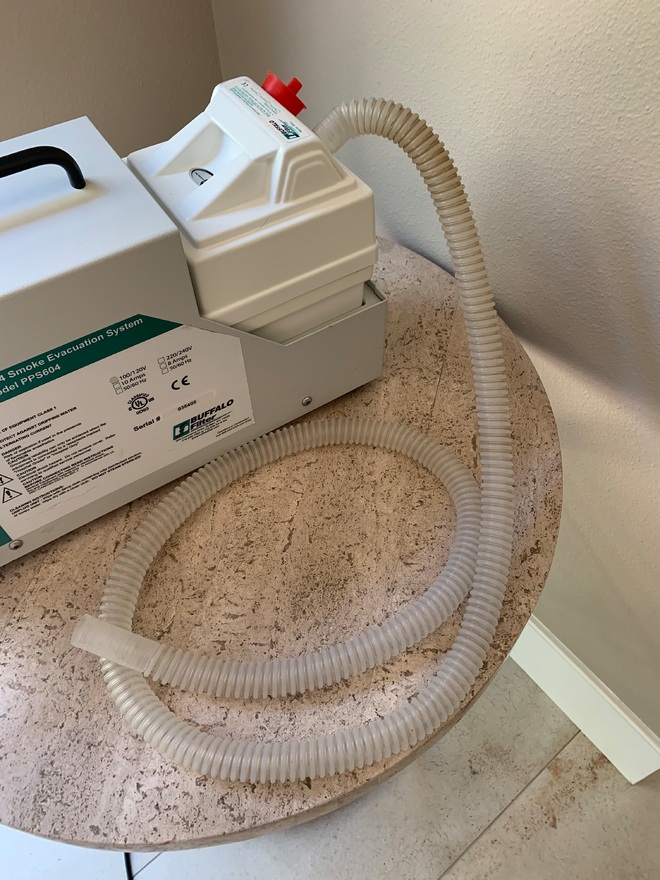

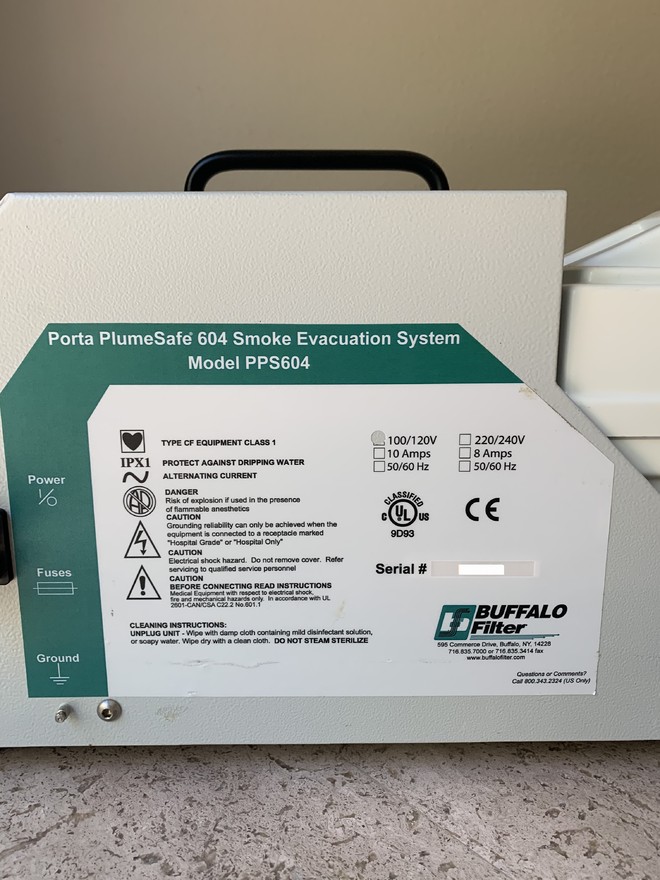

Home / Products / Accessories / Smoke Evacuator / 2006 Buffalo Filter Porta Plume Safe 603 Smoke Evacuator

2006 Buffalo Filter Porta Plume Safe 603 Smoke Evacuator

2006 Buffalo Filter Porta Plume Safe 603 Smoke Evacuator for Veterinarian and Non-Acute Care; Perfect Operating Condition & Excellent Cosmetic Condition; Reason for Selling: Closed Practice; Includes: Operators Manual, Foot Pedal, Hose & 90 Day Warranty. (jp/gre25)

$850.00

Out of stock

BUFFALO FILTER® PlumeSafe Smoke Evacuation Systems are designed to remove smoke and noxious odors produced by surgical smoke during laser, electrosurgical, ultrasonic, argon, plasma and

mechanical instrument procedures.

The PlumeSafe Smoke Evacuation Systems have been designed with a high suction, high flow rate centrifugal action pump. The ultra-quiet motor is used to draw the surgical smoke from the surgical site through the vacuum tubing and into the ViroSafe filter where the surgical smoke is processed by

a series of filters.

A single disposable filter is used to simplify the installation and removal during filter changes. The filter is completely enclosed to protect the healthcare personnel from potential contamination during filter changes. One Buffalo Filter ViroSafe filter contains four different stages within to capture the smoke plume.

The first stage filtration is a prefilter whose function is to trap and remove gross particulate and casual fluid.

The second stage filtration is ULPA grade (Ultra Low Penetration Air) filter whose high-tech patented (U.S. Patent #58740 52) design captures particulates and micro-organisms from .1 to .2 microns at an efficiency of 99.999%.

The third stage filtration uses the highest grade virgin activated carbon, especially designed for Buffalo Filter for the removal and adsorption of odors and toxic gases produced by burning tissues.

These harmful gases may constitute a health hazard to healthcare professionals who are subjected to

prolonged exposure. The activated carbon used in the PlumeSafe Smoke Evacuation Systems preferentially removes toxic organic gases rather than water vapor and provides optimal odor removal.

The fourth stage filtration is an expanded foam used to trap activated carbon fines from migrating out

of the filter. The electronic controls on the face panel of the PlumeSafe Smoke Evacuation System has been designed user friendly and facilitate unit set up and operation.

| Date Sold |

|---|

* Shipping is included in the Continental USA only. Any shipment outside the lower 48 United States will be shipped at an extra cost. If you live outside this area, please contact us for a free shipping estimate.

Related Products

Related products

-

2003 Candela Gentlelase Mini MGL – Very Low Pulses

$75,000.00Original price was: $75,000.00.$23,975.00Current price is: $23,975.00. Read more