Shop by Category

- Accessories

- Aspirator

- Cosmetics

- Digital Photography Systems

- Eyewear

- Footswitch/Foot Pedal

- Handpieces

- Infiltration Pump

- Laser Eyewear

- Microdermabrasion Devices

- Miscellaneous

- Portable Devices

- Skin Care Products and Make Up

- Skin Chillers

- Skin Sales Tools

- Smoke Evacuator

- Tips & Consumables

- Training & Business Tools

- User Manual/Operators Manual

- Les Encres

- Manufacturer

- Active Optical Systems

- Advalight

- Aerolase

- Aesthera

- Aesthetic Management Partners (AMP)

- Aesthetics Biomedical

- Aesthetika Lasers

- Agnes Medical

- Alma Lasers

- Artas

- Artemis

- Asclepion

- Bella Products Inc.

- BTL Aesthetics

- Buffalo Filter

- Candela

- Canfield

- Cartessa

- Cellsound Aesthetics

- Cenmade

- Cervello

- Chromogenex

- CoolTouch

- Cutera, Inc.

- Cynosure, Inc.

- Deka

- Dermasweep

- DiamondTome

- Dornier

- Dusa

- Eclipse Aesthetics

- Edge Systems

- Eleme

- Ellman

- Emage Medical

- Emvera

- EndyMed

- Energist

- Equipmed

- Erchonia

- Fisioline

- Focus Medical

- Formatk

- Fotona

- Fraxel

- HK Surgical

- HOYA ConBio

- Human Med

- Hydrafacial

- Ilooda

- Inmode Aesthetic

- Iridex

- Jeisys

- Lasering

- LaserOptek

- Laserscope / Iridex

- Lazerlenz

- Light Bioscience

- Lipo Ltd

- Lumenis

- Lutronic, Inc.

- Mattioli

- Medical Laser Technolgies

- Medicamat

- MeDioStar NEXT

- Merz

- Miramar Labs

- NeoGraft

- Noir

- Noir Laser Eyewear

- Novoxel

- Nuvolase

- Nylo Aesthetics

- Obagi Medical

- Omnilux

- Other

- Palomar Medical

- Parisian Peel

- Photo Therapeutics

- Profect Medical Technologies

- Quanta Systems

- Quantel

- RA Medical

- Radiancy

- Reveal

- RevecoMed

- Rohrer Aesthetics

- Sandstone

- Sano Laser

- Sciton, Inc.

- Sharplight

- Sincoheren

- Solta Medical

- Storz Medical

- SupraMedical

- Sybaritic, Inc

- Syneron, Inc.

- Syntech Laser

- Thermage, Inc.

- Thermi Aesthetics

- Ulthera, Inc

- Ultra Aesthetica

- Venus Concepts

- Vibraderm

- Viora

- Vivace

- Viveve

- Wontech

- Zeltiq

- Zimmer

- Procedure

- Acne Scars

- Acne Treatment

- Acoustic Radial Shockwaves

- Actinic Keratosis

- Age Spots

- Body Contouring

- Body Contouring – Diode

- Body Contouring – Hands Free

- Body Contouring – Radio Frequency

- Body Contouring – Ultrasound & Radio Frequency Combined

- Cavitation

- Cellulite Smoothing

- Cherry Angiomas

- Collagen Regeneration

- Complexion Analysis

- Dental

- Dry Eye

- Dynamic Muscle Stimulation

- Epidermal Renewal

- Erectile Dysfunction

- Face Contouring

- Face Oil Reduction

- Facial

- Facial Muscle Stimulation Treatment

- Facial Redness

- Fat & Cellulite Reduction

- Fat Grafting

- Fractional Skin Resurfacing

- Freckles

- Hair Restoration

- Hyperhidrosis

- Hyperpigmentation

- Incontinence

- Keloid Scar Treatment

- Laser Hair Removal

- Laser Hair Removal – Diode

- Laser Lipolysis

- Liposuction

- Lymphatic Massage/Drainage

- Melanin Reduction

- Melasma Removal

- Microdermabrasion

- Microneedling

- Muscle Sculpting

- Non-Invasive Hair Growth Treatment

- Non-Surgical

- Oxygen Skin Therapy

- Pain Relief

- Photodynamic Therapy

- Photofacial Rejuvenation

- Pigment Reduction

- Pigmented Lesion

- Podiatry

- Pore Minimizer – Minimize Enlarged Pores

- Port Wine Stains

- Psoriasis

- Reverse Photo-aging Damage

- RF Microneedling

- Rosacea Treatment

- Scalp Health

- Scar Correction

- Seborrheic Keratosis

- Skin Analysis

- Skin Chilling

- Skin Rejuvenation – Ablative

- Skin Rejuvenation – Non-Ablative

- Skin Rejuvenation – Sublative

- Skin Resurfacing

- Skin Tags

- Skin Tightening

- Skin Tightening – Eye Area

- Spider Veins

- Sterilize

- Stretch Marks Removal

- Sun Spots

- Surgical

- Sweat Reducer

- Tattoo Removal

- Toenail Fungus

- Transepidermal Delivery

- Ulcer/Wound Healing

- Vaginal Rejuvenation

- Vascular Lesions

- Vascular Structure

- Vein Removal

- Warts

- Wrinkle Reduction

- User Manuals

- Wavelength

- 10,600 nm (CO2)

- 1060 nm (Diode)

- 1064 nm (Diode)

- 1064 nm (Nd Yag Long Pulse)

- 1064 nm & 755 nm

- 1064 nm, 755 nm & IPL

- 1100 – 1800 nm (Infrared)

- 1319 nm (Infrared Nd Yag)

- 1320 nm (Infrared Nd Yag)

- 1400 nm (Erbium Glass)

- 1440 nm Nd Yag

- 1450 nm (Diode)

- 1470 nm

- 1500 nm (Erbium Glass)

- 1540 nm Erbium Glass

- 1550 nm Erbium Glass

- 1565nm

- 1750nm (Infrared)

- 1927 nm (Thulium)

- 2790 nm (Erbium YSGG)

- 2940 nm (Erbium Yag)

- 308 nm (Xenon Chloride)

- 532 nm (KTP)

- 532 nm / 1064 nm (KTP / Nd Yag – Q-Switched)

- 585 nm (Pulsed Dye)

- 595 nm (Pulsed Dye)

- 635 nm (Diode)

- 650-660 nm (Diode)

- 670 nm

- 680 nm (Red Diode)

- 694 nm (Ruby)

- 700 nm

- 755 nm (Alexandrite)

- 755 nm (Diode)

- 800 nm (Diode)

- 805 nm (Diode)

- 808 nm

- 810 nm (Diode)

- 850nm (Infrared)

- 900 nm (Diode)

- 980nm (Infrared Diode)

- Acoustic Wave Therapy AWT

- AFT (Advanced Fluorescence Technology)

- AMP – Active Magnetic Pulse

- CO2

- Direct Bio-Electrical Muscle Stimulation

- ElectoFusion

- EMS (Electrical Muscle Stimulation)

- HIFEM (High Intensity Focused

- IPL (Broad Spectrum)

- LED (Light Emitted Diodes)

- LIESWT – Low- Intensity Extracorporeal Shock Wave Therapy

- Multi-Wavelength

- Nitrogen Plasma

- Radio Frequency

- Radio Frequency – Bipolar

- Radio Frequency – Monopolar

- Radio Frequency – Unipolar

- Shock Wave Therapy

- TMA – Thermo-Mechanical Action

- Tripollar RF

- Ultrasound

- Ultrasound & Radio Frequency

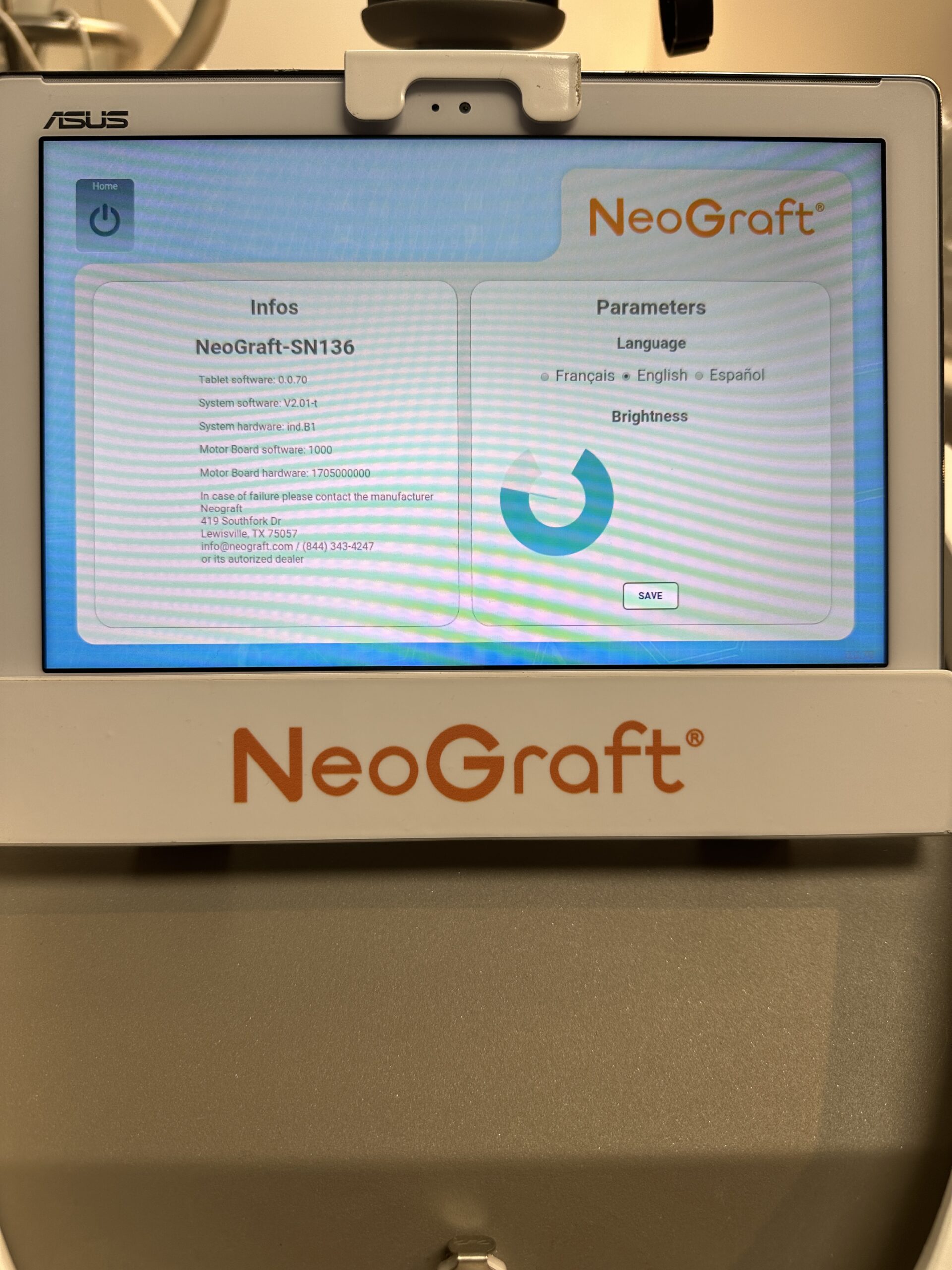

Home / Products / Manufacturer / NeoGraft / 2018 Neograft Solutions Neograft 2.0 – Automated Hair Restoration – INCLUDES CONSUMABLE PURCHASING SUPPORT – Free Shipping & Warranty (km/har)

2018 Neograft Solutions Neograft 2.0 – Automated Hair Restoration – INCLUDES CONSUMABLE PURCHASING SUPPORT – Free Shipping & Warranty (km/har)

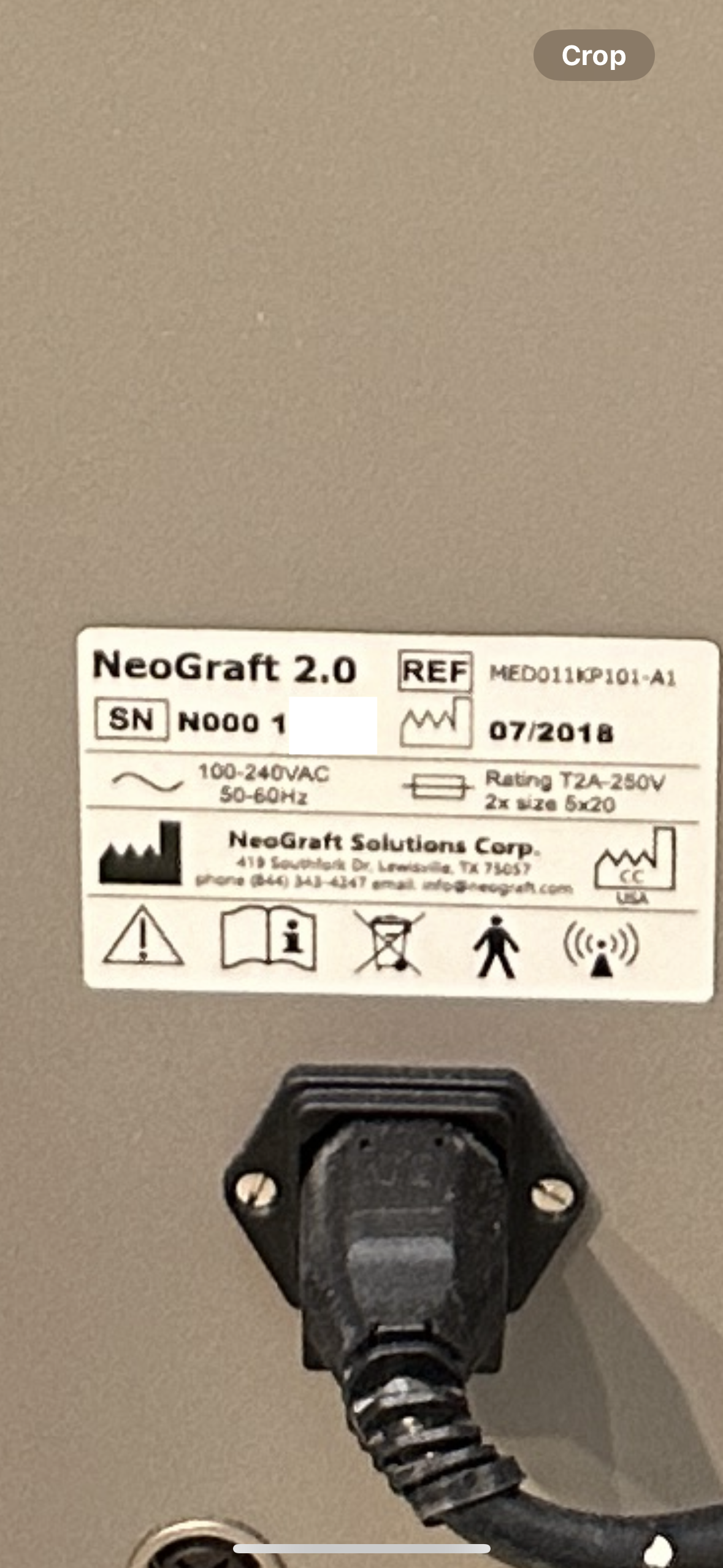

2018 Neograft Solutions NeoGraft 2.0 – Automated Hair Restoration System;

SELLER HAS AGREED TO REPRESENT THIS DEVICE FOR THE PURCHASE OF NEOGRAFT TREATMENT CONSUMABLES AND FOR SERVICE IN THE EVENT SERVICE IS NEEDED; RECERTIFICATION FEE WILL NOT BE REQUIRED IN ORDER TO OBTAIN THE CONSUMABLES; SELLER ALSO MAY BE AVAILABLE TO PROVIDE TRAINING AT A NOMINAL FEE;

Manufactured 07/2018; Perfect Cosmetic and Operating Condition, Single Owner, Only Used for 4 Cases; Reason for Selling: No Longer Offering this Service;

Remaining Grafts: 49,270; Owner will be available to add more Grafts through Venus Concepts as Needed;

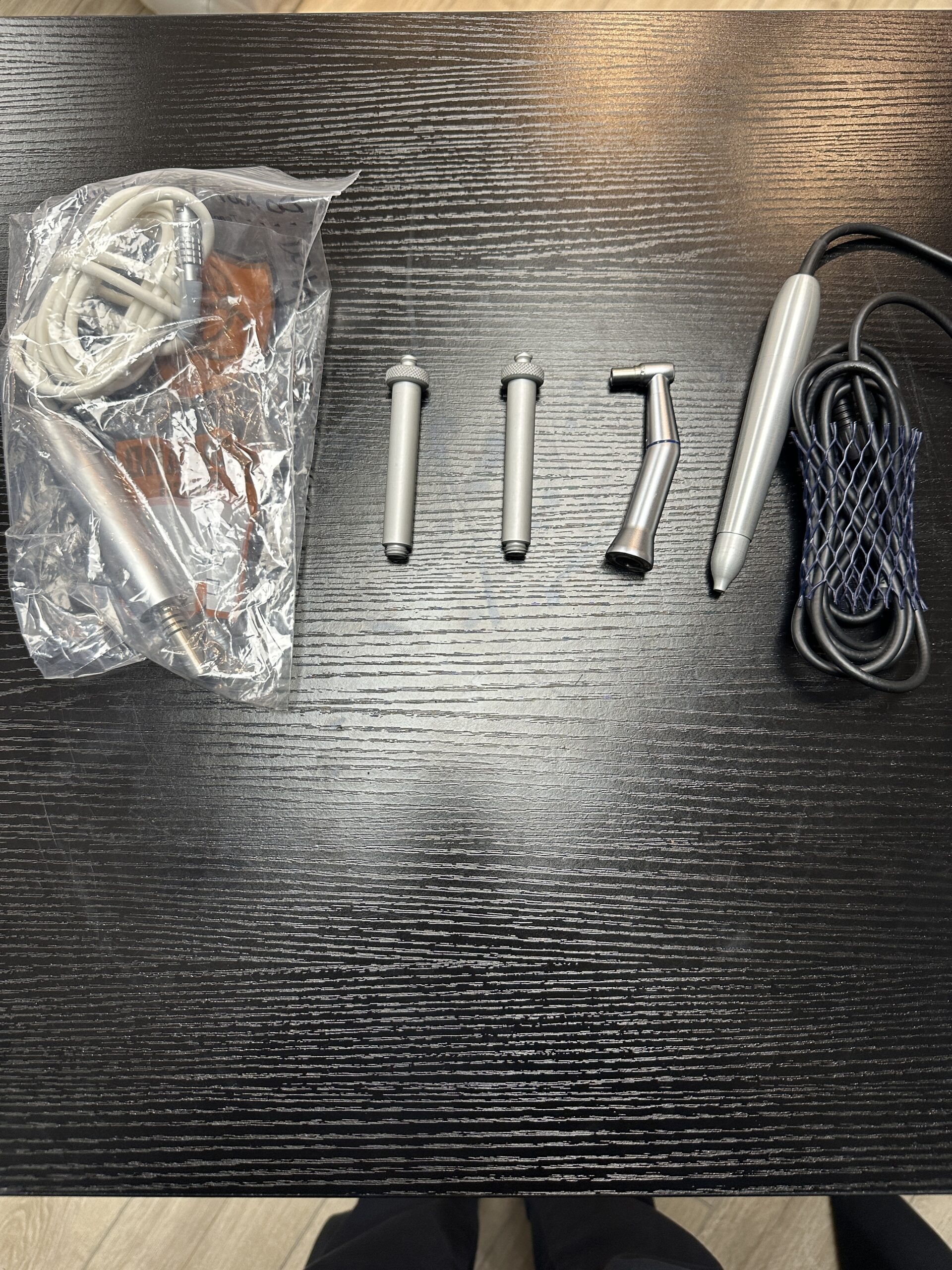

Includes: Handpieces, Key, Footswitch, Interlock, 90 Day Warranty, and Free Shipping in the Continental USA.(km/har8)

Shipping to Canada $250 Extra;

This System Can be Shipped to Anywhere in the World at an Extra Charge.

This Equipment is Fully Functional, With No Error Messages, Ready for Use, and Ready to Ship. Actual Photos of the Device are Displayed.

Warranty Includes Cost of Parts, Labor, & Shipping or Travel.

Financing Available. Training is Available at an Additional Cost.

See a Video of this Device Below:

$120,000.00 Original price was: $120,000.00.$16,975.00Current price is: $16,975.00.

Out of stock

NeoGraft 2.0 CONSUMABLES

Punches (0.8mm), $90 per Punch, 5 Punches Average Per Treatment = $450;

Cartridges/Canister Kits $40 each, Approximately 2 Needed Per Treatement = $80;

Tubing + Suction Set, $40 each, 1 Needed Per Treatment = $40;

Storage Cups/Trays + Filters, 1 Needed Per Treatment = $30

Total Approximate Cost Per Procedure = $600

NeoGraft 2.0 PRODUCT SPECIFICATIONS

Dimensions: W × D × H (not packed): 45 × 40 × 100 cm, (17.7 × 15.8 × 39.4)

Weight: 36 kg, (79.4 lbs)

Color: White and gray

Electrical requirements: 100 – 240 VAC, 50 – 60 Hz, 100VA

Main fuses: T2AH-250VAC (qty = 2), Size 5 x 20

Power cord: USA and Canada type:

Rating 10 amp, 125 VAC, hospital grade,

UL and CSA approved

Operating temperature: +15°C to +25°C (+59°F to +77°F)

Humidity conditions: Max. 60%

Maximum internal pressure: 2.5 bars

Implantation handpiece pressure: 0 to 2.5 bars

Contra-angle head rotation speed: 0 to 3000 rpm

Maximum vacuum: -800 mbars

Device Classification: I in U.S.A

Applied parts: B type

NeoGraft 2.0 MANUFACTURER NOTES

NeoGraft®’s revolutionary automated Follicular Unit Extraction (FUE) and implantation system makes it easier than ever for physicians to provide the hair restoration procedures that patients want.

NeoGraft® Hair Restoration System

The Trusted Hair Restoration Solution

NeoGraft®’s revolutionary automated Follicular Unit Extraction (FUE) and implantation technology leaves no linear scar and is minimally invasive with fast patient recovery.

Excellent Results For Hair Restoration With A Minimally Invasive Treatment

NeoGraft® is the industry pioneer and market leader with one of the first automated FUE system in the hair restoration market. NeoGraft®’s harvesting, site-making and implantation functions make it easier than ever for physicians to address hair loss and provide the hair restoration procedures that patients want. The inefficiencies of manual extractions and implants have been eliminated, and replaced it with advanced technology that provides patients with the benefits of the FUE procedure while also enabling physicians to perform fast, effective, safe hair transplants that yield superior clinical results.

Optimized Work Flow

The incorporation of a double-jointed arm and improved ergonomics results in faster and more comfortable medical procedures for both patients and physicians.

New contra angle eliminates loss of fluid and protects grafts through vacuum seal

Recipient site creation handpiece delivers more standardized implants

No-touch implanter offers the least amount of bulb trauma

Autoclavable handpieces offer sterilizable and cost-effective tools

Pneumatic Motor And Smart Drive Torque Technology

The piston-driven motor delivers precise pressure control for both extraction and implantation.

Smart Drive Torque Technology delivers 100% torque to the contra angle/punch, for continuous rotation and the smoothest entry.

Consistent suction and spin lead to standardized extractions, high quality grafts, and superior patient outcomes

Intuitive Touchscreen Interface

GUI delivers user friendly, intuitive, interactive experience

Treatment screens allow users to easily switch between two modes – extraction and implantation

User management tools help track and improve performance of treatment providers

* Shipping is included in the Continental USA only. Any shipment outside the lower 48 United States will be shipped at an extra cost. If you live outside this area, please contact us for a free shipping estimate.

Related Products

Related products

-

2013 Medicamat Neograft S.A.F.E.R. Automated Hair Restoration System – with Accessories – Free Shipping (km/kin)s

$98,000.00Original price was: $98,000.00.$8,975.00Current price is: $8,975.00. Read more -

2020 Sunetics Model G Hair Restoration Diode Continuous Wave Red Light Laser – Perfect Condition – Only 110 Hours of Use- Free Shipping (km/ber)

$60,000.00Original price was: $60,000.00.$15,975.00Current price is: $15,975.00. Read more -

2014 Medicamat Neograft S.A.F.E.R. Automated Hair Restoration System (km/ss)x

$98,000.00Original price was: $98,000.00.$15,975.00Current price is: $15,975.00. Read more